Filta-DCHS Compared with other similar products, dry chemical washing air filtration system has the following advantages:

Optimized filter box structure;

Use unique dry chemical adsorption filtration combination;

Filter material adsorption capacity is strong, saturated adsorption capacity;

The type and concentration range of pollutants adsorbed by filter material are large, and the removal effect is good.

It has strong effect of disinfection and sterilization;

The filter material has a good PH adjustment function, can avoid the acidification or alkalization of the filter bed; Filter material structure strength, will not shatter, do not need to repair loss;

Convenient replacement of filter material; High efficiency, small volume;

Modular assembly can be realized;

Filter material does not contain heavy metals and other toxic substances, ineffective filter material can be treated as a general solid waste.

Action principle

Dry chemical adsorption, also known as dry chemical washing, began to be used in the workplace and indoor air quality purification in Europe and The United States in the 1950s and 1960s. Dry chemical filtration is a complex process dominated by mass transfer, adsorption and chemical oxidation. Dry chemical filter material mixed with adsorption materials as well as chemical oxidant of chemical active substances, when air through the filter material layer air contains pollutants (such as H2S, NH3, and formaldehyde, organic acids, alcohols, ethers, xylene, acetone, and other VOCs) is adsorbed to the surface of the filter material, and react with the chemical composition of filter material, To harmless products (such as salt, CO2, and water). In the dry chemical adsorption filtration device, dry chemical adsorption filter material plays a crucial role, it not only provides a strong adsorption force on gas molecules, but also provides the adsorption of gas molecules for oxidation, decomposition, transformation of the active chemical components required, at the same time, Filter material design also needs to be conducive to the formation of chemical reaction can effectively develop the appropriate conditions (such as humidity, temperature, PH), but also need to be able to carry a sufficient amount of chemical active substances, so that the filter material can play a long-term and stable function. Therefore, excellent chemical filter material must have a large enough specific surface area, bearing suitable and as much as possible chemical active substances. But the carrying capacity of chemical substances will also affect the surface of the adsorption material, so as to reduce the adsorption capacity of the filter material, so the excellent filter material needs to have a better composition ratio.

Filta-DCHS Efficient dry chemical filter material basic performance table and use object

| model | Bulk density (g/L) | Porosity (%) | Specific surface area (㎡/g) | CC14 (mg/g) | H2S adsorption capacity (g/g) | VOC adsorption (g/g) | Types of waste gas treated | EBRT (S) |

| DCA-1 | 1000 | 35 | 50 | 30 | 0.4 | 0.1 | A broad-spectrum odor and VOCs remover, it has a remarkable ability to remove H2S, SO2, Nox, formaldehyde, ethylene and other organic substances, and can effectively kill viruses, bacteria, molds and spores, and the efficiency can reach 99.9% | 1-3 |

| DCA-2 | 800 | 35 | 86 | 43.4 | 0.3 | 0.08 | Exhaust gas containing H2S, Cl2, NH3, and VOC components | 1-3 |

| DCA-3 | 800 | 40 | 402 | 220 | 0.25 | 0.15 | All kinds of toxic and harmful gas components can be effectively removed, and it has a good overall removal effect on broad-spectrum organic components such as H2S, mercaptan, sulfide, and formaldehyde. Strong physical adsorption capacity. | 1-3

|

Features of Filta-DCHS high-efficiency dry chemical filter media:

High oxidant loading capacity (hydrophilic porous core stores excess active compounds)

Strong ability to eliminate odors (saturated adsorption capacity for hydrogen sulfide, Cl2 and other polluting components reaches more than 30%, and removal efficiency reaches more than 99%), it is not easy to be damaged and hardened, and the filling height can reach more than 4 meters

Stable performance and long service life

Inactivated filter media can be recycled

Small pressure drop (less than 500Pa)

Short residence time (less than 2s)

The removal efficiency that the Filta-DCHS dry chemical adsorption system can achieve (taking the removal of H2S as an example)

| unit | Inlet concentration | Odor characteristics | Average removal rate % |

| Odor concentration | OU | 10000 | -- | ≥99 |

| NH3 | MG/m³ | 5.20 | irritating | ≥90 |

| H2S | MG/m³ | 60 | rotten eggs | ≥99.0 |

| Ethylamine | MG/m³ | 1.20 | fishy, irritating | ≥99.0 |

| Dimethyl Sulfide DMS | MG/m³ | 12 | sulfuric acid | ≥99.0 |

| SO 2 | MG/m³ | 30 | sulfuric acid | ≥95 |

The treatment effect that Filta-DCHS dry chemical filtration system can achieve (taking the removal of mixed components as an example)

| Engineering one | Engineering II |

| pollutants | import | Export | % | import | Export | % |

| Odor concentration | 12586 | 110 | >99% | 15677 | 140 | >99% |

| Methyl Mercaptan MM (ppm) | 5.2 | ND | >99% | 1.1 | ND | >99% |

| Dimethyl sulfide DMS (ppm) | 6.3 | ND | >99% | 0.45 | ND | >99% |

| Dimethyl disulfide DMS (ppm) | 0.9 | ND | >99% | 0.33 | ND | >99% |

Box Design and Auxiliary Equipment of Filta-DCHS High Efficiency Dry Chemical Adsorption System

Collection system

It is composed of indoor gas collecting pipeline, conveying pipeline, fan and exhaust pipe. The gas to be treated is collected and transported to the treatment system for filtration and purification, and the treated gas is discharged into the atmosphere through the exhaust port or exhaust cylinder.

The collection system adopts different materials and structures according to the size of the building. The material of the air duct can be selected from stainless steel, galvanized steel, HDPP, FRP, etc. The interior of the dry chemical adsorption box adopts a multi-layered arrangement of filter materials, so that the residence time of the filter bed and the approaching wind speed both meet the design standards. The overall structure of the box is high in strength, and there are special filter material addition ports, discharge ports, sampling ports, and observation ports, which are convenient for inspection, evaluation, and replacement of filter materials. It can be equipped with a filter differential meter and an outlet air quality detection instrument to realize remote automatic monitoring.

Pre-filter

In order to ensure that the dry chemical adsorbent can work normally and will not have adverse effects on the adsorbent due to dust, microorganisms and moisture in the air, it is generally necessary to set a pre-filter layer in front of the dry filter bed. The pre-filter of the best material is selected according to the type and nature of the odor to be treated. Generally, primary-efficiency or medium-efficiency non-woven filters or filter bags are used. When the air intake humidity is high, a dehumidifying cotton filter layer is added. For indoor air purification occasions such as stations, docks, shopping malls, commercial office buildings, etc., filter materials with antibacterial effects can be selected. Although our dry chemical filter material has a strong effect of eliminating bacteria, adding a filter with a bacteria-filtering effect in the front channel can further ensure the sterilization effect of the air and prevent the spread of bacteria and viruses in the air.

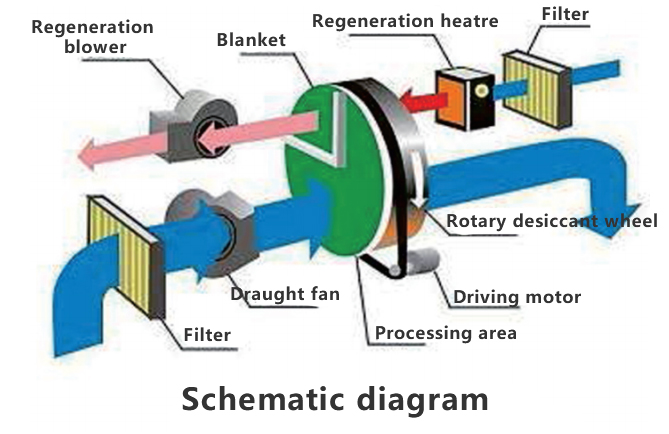

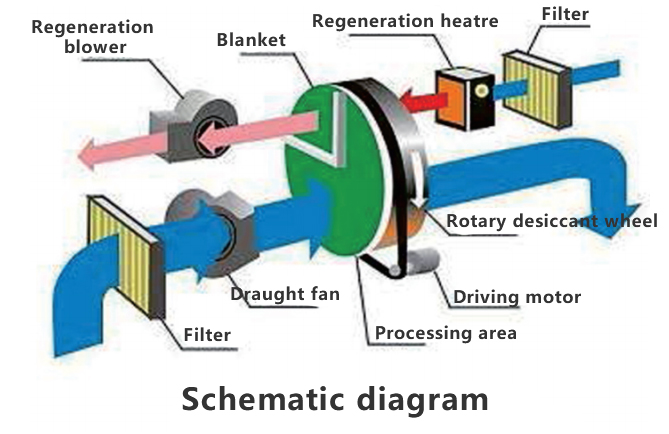

Dehumidification system

When the moisture content of the exhaust gas is very high and close to saturation, in order to ensure the best performance of the dry chemical adsorption device, it is necessary to perform dehumidification treatment before the dry chemical adsorption treatment, so that the humidity of the intake air is lower than Dew point (generally requires low relative humidity 75%), a dehumidification system needs to be set at this time. Our company provides customers with dedicated high-efficiency, reliable and low-energy dehumidification solutions. Using advanced rotary dehumidification systems, energy consumption is reduced by 30%-50% compared to cooling dehumidification systems.